Combine UV-LED printing and laser engraving to create a one-of-a-kind keepsake that can be presented as an award or given as a cherished keepsake.

We’re going to create a full-color product with dimension and texture. Each element—from the photo to the text to the graphics—is personalized for the recipient. Creative pieces like these impress customers and make you stand out from the crowd.

Mix & Match

Elevate It to the Big Leagues by Pairing a UV Printer and a Laser to Create a One-of-a-Kind Piece that Will Be a Hit with Your Customers

By George Privateer, Rowmark

Combine UV-LED printing and laser engraving to create a one-of-a-kind keepsake that can be presented as an award or given as a cherished keepsake.

We’re going to create a full-color product with dimension and texture. Each element—from the photo to the text to the graphics—is personalized for the recipient. Creative pieces like these impress customers and make you stand out from the crowd.

OUR MATERIALS

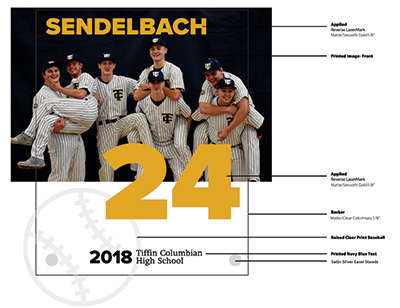

Rowmark ColorHues Matte Clear 1⁄8-in. translucent engraving plastic as the base layer we will UV print

Rowmark LaserMark Reverse Matte Clear/Gold 1⁄8-in. as the gold applique for the player names and numbers

Satin Silver Easel Display System

OUR EQUIPMENT

CO2 laser for cutting our materials

UV printer for printing color and raised images, graphic, and text directly onto the substrate. We used Direct Color Systems’ 1024 UV MVP15 printer.

STEP 1: LASER CUTTING

First, we used our laser to vector cut our base material (the ColorHues) to the size we want the finished product to be. I cut mine to 8 in. by 10 in. I also cut two .25-in.-diameter holes at the bottom of the award for the finishing hardware.

STEP 2: DESIGN

We used CorelDRAW X8 to design this piece. The process of designing artwork for the UV printer is similar to creating designs for the laser.

We started with our 8 in. by 10 in. background and added our baseball graphic and text.

There were two important considerations when we created the baseball graphic. We needed to create breaks in the image to accommodate the black text and the gold applique number. This prevents the clear, raised ink of the baseball from running over the black text or creating an uneven surface for the mounted applique.

STEP 3: UV PRINTING

Our UV printers' first and second passes (above) printed the team photo and the text. The third (below) prints layers in clear ink to create the raised image of the baseball.

We’re going to use the UV printer to print the team photo, black text at the bottom of the award, and the raised clear baseball directly onto the ColorHues material.

Because we’re using a UV printer from DCS, we’re able to print a true edge-to-edge image (known as “full bleed” in the printing industry) and build up ink to create dimension and texture, even with clear ink. If your UV printer can’t do this, you may need to print the image on a larger piece of ColorHues before cutting it at the image’s edge or simply print a flat image of a baseball.

This award will require three passes through the UV printer: one to print the team photo (shown), the second to print the black text, and the third to create the raised clear baseball.

You can see the UV-LED light curing the ink on each pass. As soon as the team photo is printed, the award is ready to go back in the printer to print the text.

Shown are two awards with the team photo and text already printed and cured. Both are ready for the final pass to create the clear baseball.

Tip: Making more than a few? Depending on your printer’s bed size and the size of the base, you may be able to send multiple pieces through on each pass. You can certainly complete all three printing passes for each piece instead; because the UV lights immediately cure the ink, you don’t need to add in drying time between passes.

The printer layers the clear ink to create the raised baseball image. UV printers’ software lets the user set the color and amount of ink used so that you can add a tactile dimension. You could print a flat or colored baseball (or other image), but the clear, raised graphic will really impress your customers, recipients, and everyone else who sees it.

STEP 4: APPLIQUE

Use your laser engraver to vector cut the gold applique names and numbers. Then, apply them to the UV printed substrate.

Tip: If you’re creating pieces for multiple team members, look at the players’ last names and numbers before starting this project to see if any will require special space considerations due to the number or width of the characters.

STEP 5: HARDWARE

The last step is to attach the display hardware.

We used the two-piece Rowmark Fisso Desk Satin Silver Easel Display System so that these could be easily displayed on a desk, on a shelf, or in a trophy case.

Tip: To turn these into wall hangings, place the holes at the top of the piece in Step 1 and use Rowmark Fisso Stainless Steel Stand-offs.

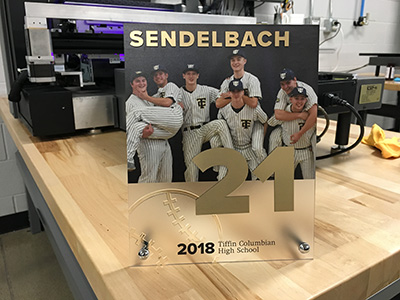

THE RESULTS

The finished product (shown) is a custom piece that features full color, texture, and dimension in addition to the team photo and personalized name and number. These pieces can easily be produced for an entire team, with each player getting a unique award or keepsake.

By mixing media and fabrication techniques, you can create awards and personalized pieces that will keep your customers coming back for years to come.

Rowmark’s content and media manager, George Privateer has been with the Findlay, OH, supplier for more than 14 years. This amazing piece was designed by Jessica Fletcher, Rowmark’s design and trade show manager, and fabricated by Lydea Ziebold, Rowmark graphics technician.

Rowmark is a leading manufacturer of engravable sheet plastic for the signage, engraving, and awards markets. Its products are sold through an extensive network of Rowmark distributors around the world. Rowmark companies include Johnson Plastics Plus (including LaserBits and Bur-Lane), Innovative Plastics Incorporated (IPI) and Premier Material Concepts (PMC). Visit www.rowmark.com to learn more.

Get more on UV printing in the Insights article library!