UV printing—and more specifically UV-LED inkjet printing—has been around for many years. Still, it has only been in the past 2 to 3 years that the industry has seen several companies manufacture a small-format (SF), entry-level flatbed printer that would lend itself to broad-based acceptance in the engraving and awards market. The SF table sizes accept products up to a 12 in. by 24 in. and up to 6 in. in height, and these printers are beginning to become popular profit centers.

A New Direction

Printing Braille Signage? UV-LED Printing Makes It Possible

By Blair Allen, Direct Color Systems

(Originally published in the May 2013 issue of Recognition Review.)

UV printing—and more specifically UV-LED inkjet printing—has been around for many years. Still, it has only been in the past 2 to 3 years that the industry has seen several companies manufacture a small-format (SF), entry-level flatbed printer that would lend itself to broad-based acceptance in the engraving and awards market. The SF table sizes accept products up to a 12 in. by 24 in. and up to 6 in. in height, and these printers are beginning to become popular profit centers.

UV printing—and more specifically UV-LED inkjet printing—has been around for many years. Still, it has only been in the past 2 to 3 years that the industry has seen several companies manufacture a small-format (SF), entry-level flatbed printer that would lend itself to broad-based acceptance in the engraving and awards market. The SF table sizes accept products up to a 12 in. by 24 in. and up to 6 in. in height, and these printers are beginning to become popular profit centers.

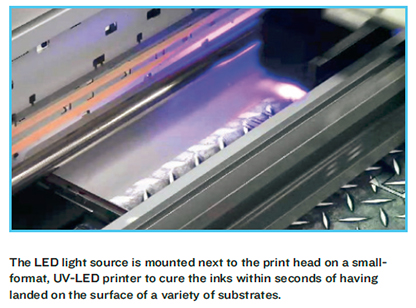

First, let’s define what UV-LED direct inkjet printing is. Ultraviolet (UV) inks are used in this process. UV inks cure and dry almost instantly when exposed to a specific light wavelength and energy. In the case of SF UV printers, a light emitting diode (LED) is used. LEDs are being used in many applications, from TVs to house lighting, and their use is expanding as their manufacturing cost decreases. Advantages to the SF direct-printers are their small size, ability to instantly turn on and off, long length of operational life (10,000 to 20,000 hours), and reduced heat from the light source. Without an LED source that offers these benefits, SF UV printers wouldn’t be possible.

Why are awards businesses and engravers embracing this style of inkjet printer? UV inkjet printers have several benefits over previous technologies, such as solvent inkjet printers. Here are four key benefits:

Opaque White Ink

As awards retailers know, there are many products that need to be digitally imaged to or marked on. The vast majority of these products are not white. Full process color digital printing, or CMYK (Cyan, Magenta, Yellow, and blacK), requires a white background or substrate in order to see what has been printed. In the absence of a white substrate and without an opaque white to “underbase” your CMYK onto, the printed image is either the wrong color or cannot be viewed at all in the case of a black substrate.

As awards retailers know, there are many products that need to be digitally imaged to or marked on. The vast majority of these products are not white. Full process color digital printing, or CMYK (Cyan, Magenta, Yellow, and blacK), requires a white background or substrate in order to see what has been printed. In the absence of a white substrate and without an opaque white to “underbase” your CMYK onto, the printed image is either the wrong color or cannot be viewed at all in the case of a black substrate.

Most UV-LED printers offer staggered heads or inline printing when offering a white ink option so you can quickly and accurately print a white layer as a prime layer. Many companies also offer software that can automatically trap or shrink the white layer so none of it is seen by the naked eye.

Broad Range of Substrates That Will Accept UV Inks

UV inks offer one of the widest range of substrate options for imaging. Because UV printing doesn’t rely on the absorbency of the substrate to dictate the dot gain or resolution of the image (like the need for photo paper for your desktop home printer), the UV image quality on many different substrates is consistent and high quality. Substrate acceptability is judged by adhesion. In the case of some substrates such as glass, bare metals, glazed ceramic tiles, and polypropylene, a primer or adhesion promoter is often used to ensure good adhesion of the inks to the substrate. Many other substrates—including wood, acrylics, acrylonitrile butadiene styrene (ABS), polycarbonate, leather, vinyl, and painted or coated metals—require no preparation and offer good adhesion for the UV inks. Recently, more custom products, such as coated metals, have gone on the market for UV printers to avoid the extra step of applying the primer/adhesion promoter.

Because UV-LED printers can place an opaque white “underbase” just beneath the printed colors, clear color images can be printed onto dark substrates, like this hockey puck.

Reduced Inkjet Nozzle/Head Maintenance

UV inkjet inks require less maintenance for nozzle and print head health. This is due largely to their makeup, which has little or no volatile organic compounds (VOCs, commonly known as solvents) content. As a result, UV inkjet inks do not rely on evaporation for curing and drying, so they do not “dry up” in the nozzles and clog the print head. More than 85% of the liquid volume of UV ink that is jetted ends up on the substrate. Conversely, solvent inkjet inks contain high levels of VOCs. More than 85% of the liquid volume that is jetted from a solvent print head does not stay on the substrate. This liquid volume consists of a high concentration of VOCs and gets evaporated into the air. This same rate of evaporation exists in the print head and at the nozzles when they are exposed to air. This can contribute to clogged nozzles over time.

Quality and Durability of Finished Print

The image quality of the SF UV printers is very high and consistent even when compared across many different types of substrates. Resolution can range as high as 5,760 dpi with droplet sizes as low as 1.5 picoliters. UV inks, when cured, are extremely durable. They often get described as “liquid plastic” inks. Once proper adhesion to the substrate is established, the resistance to solvents and abrasion is very good As an example, many UV inks are impervious to strong solvents such as acetone. UV inks are also UV stable when exposed to sunlight since they contain pigments as colorants. That makes UV inks well suited for many exterior applications.

The image quality of the SF UV printers is very high and consistent even when compared across many different types of substrates. Resolution can range as high as 5,760 dpi with droplet sizes as low as 1.5 picoliters. UV inks, when cured, are extremely durable. They often get described as “liquid plastic” inks. Once proper adhesion to the substrate is established, the resistance to solvents and abrasion is very good As an example, many UV inks are impervious to strong solvents such as acetone. UV inks are also UV stable when exposed to sunlight since they contain pigments as colorants. That makes UV inks well suited for many exterior applications.

The products produced on an SF UV printer are vast and varied. For an awards and engraving shop, this type of printer can add color to many of the current products they produce. One hundred percent of the products they produce now may not be UV printable, but in many cases the vast majority is printable. Acrylic awards are typically a very compatible product. Due to the vibrant colors achieved with the opaque white ink, the images can be very dynamic. Combinations of both first and second surface printing also offer unique appearances that could only be achieved through screen printing previously. The opaque white option is also a key component when reviewing the use of this process with other awards because it allows for impressive images to be printed on anything from MDF wood grain to black metal plates.

UV-LED printing isn’t slow either. In production modes, full color marking or imaging can be achieved on an SF UV printer at resolutions of 720 by 1440 dpi that will imprint 80 sq in. in approximately 1 minute. That means you can save time by having names printed onto trophy plates in addition to creating full-color acrylic awards you weren’t able to make before.

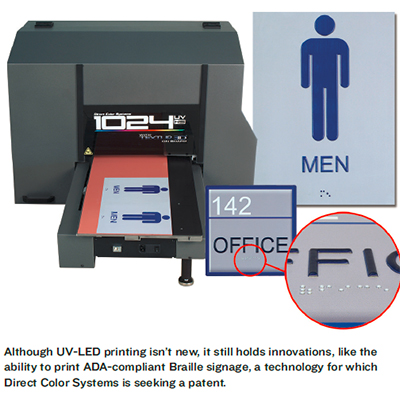

One feature unique to UV inkjet printers is the ability to create a textured or raised image. As discussed previously, the UV inks cure almost instantly when exposed to the correct light source. Because the LED light source is mounted beside the print head, the inks are cured within seconds of having landed on the surface of the substrate. Using this technology, manufacturers of these printers now offer the ability to texture an image. This is similar to an embossing feature. This new technology offers the operator the ability to raise any part of the image to create a three-dimensional look and feel. Take this concept to the next level, and you can print an ADA-compliant sign. A standard 6-in.-by-8-in. men’s restroom sign, in color with raised Braille, can be printed in less than 5 minutes on a UV-LED printer.

There have been many new developments in this field in the past 2 years, and more exciting new features will continue to be introduced.

UV-LED printing allows for the printing of three-dimensional graphics, like these Textured™ smart-phone cases.

Blair Allen is president of Direct Color Systems (DCS), a leading manufacturer of small-form, direct-to-substrate printers. In the plastics business for more than 15 years and with DCS since its inception in 1995, Blair has extensive knowledge of the printing and sheet plastic industry and a great contact base in the United States and internationally. Connecticut-based Direct Color Systems engineers, manufactures, and markets small-format, direct-to-substrate UV-LED inkjet printers and solvent inkjet printers. DCS also offers small-format flexible media/roll printers, thermal ribbon badge printers, and a complete line of printing supplies. The company has an office in Portugal and distributors in more than 30 countries. Visit www.directcolorsystems.com.